February 2023

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in February 2023 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

Reporting organic impurity content

Ph. Eur. status in Europe

Ph. Eur. status in Britain

Checking CEPs

January 2023

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in January 2023 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

Reporting impurities

Dissolution profiling of biobatches

Specifications in the Dossier

Polymorphism

December 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in December 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

SOPs in the Dossier

Mass Balance

Reviewing an IMPD or Module 3

November 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in November 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

Updating a QOS

Compatibility

Reduced testing of starting materials

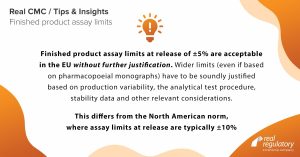

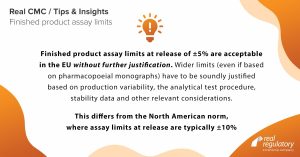

Finished product assay limits

Ingredients in the eAF

Otober 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in October 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

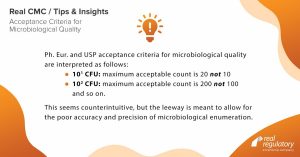

Acceptance Criteria for Microbiological Quality

EPCRS

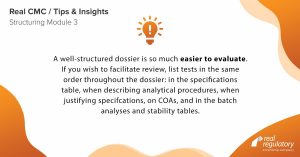

Structuring Module 3

September 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in September 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

EMA Training Materials

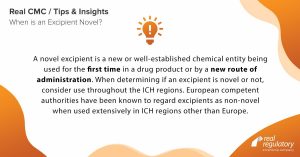

When is an Excipient Novel?

IMPDs for Small Molecule Drugs

Leaching and Sorption

Dissolution Limits for Generic SODs

August 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in August 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

Extractables

July 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in July 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

Cross-Checking of Formulae

Secondary & Tertiary Packaging

Drug Substance Specifications

Biowaivers for SODs

June 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in June 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

The EDQM Knowledge Database

Revision of Nitrosamine Risk Assessments

ICH Training Materials

Related Substances Specifications

Unidentified Impurities in Fixed Dose Combination Products

May 2022

Real CMC Tips and Insights

Since the beginning of July 2020, we have published weekly Regulatory tips and insights from our Regulatory experts on our Real Regulatory LinkedIn page, as a service to our followers. The tips we published in May 2022 are collected here, for convenience. Make sure you follow Real Regulatory Ltd and Real CMC for regulatory news, reports and hints.

EudraGMDP & MHRA-GMDP

ASMF Version Discrepancies

The Applicant’s Drug Substance Module